Cases and stories

It is in the process, the product design, and the material specification that you define the keys to success. The machine must guarantee the sufficient condition control that allows a repetitive and stable process that maximizes the output and minimizes the energy consumption.

Cellulose dry forming

Our client is a pioneer in dry forming technology, which means they’re leading the way in creating 3D shapes without using water to dissolve cellulose. This method offers a great alternative to plastic packaging because it’s cost-effective, uses materials that are completely renewable, and is efficient in both time and resources.

Dry forming combines two techniques, airlaid formation and high pressure, into one process that uses very little water and energy. This results in much lower CO2 emissions.

Thanks to Fimtech’s expertise in disposable hygiene products and new production methods, we developed Yangi’s Cellera™ dryforming machine. This technology makes it easier and more efficient to ramp up production in industry, which is a big step forward in making manufacturing more sustainable. Read more about the project.

Lightweight drink pouch

For over 20 years, we’ve been proud to serve as our customers’ technology partner, playing a key role in developing high-speed production methods for lightweight stand-up pouches in the dairy and beverage market.

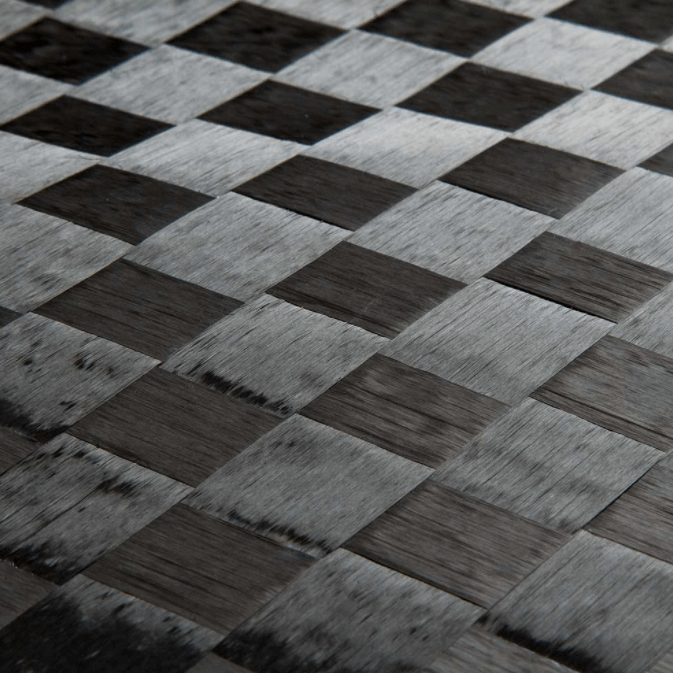

Industial weaving machine

In collaboration with our customer, a market leader in its segment, we’ve jointly refined and validated concepts for a new industrial tape weaving machine designed for spread tow fabrics.

Mono-dose applicator

We assisted in the development of this patented product and its production facility. This versatile flat pad comes in a wide range of designs for hygienically dispensing and applying any liquid or powder. It can dispense and apply a diverse array of products in a hygienic manner. With single, dual, or multi-chamber designs, it’s easy to properly mix or activate solutions.

Product development

Fimtech has played a vital role in mechanical development and design of various products for our customers. We start from the initial idea, find suitable technical solutions, carry out the design process, produce prototypes, conduct qualification tests, refine the design, and assist in finding and validating suppliers for mass production. Additionally, we can also offer assembly and production services in our facilities to further support our customers.

A good example is the VikingArm.

And much more …

Prior to Fimtech our founders had plural years of experience building machines for diapers, tampons, and sanitary napkins for the Swedish hygeen company. The most advanced machines developed here in Tønsberg are even after 25 years, still today producing 1000 diapers per minute. We make machines that last!