Products

Over the years we have worked with many customers from different industries and learned to look for synergies between different very competent, but highly specialized technologies.

“A challenge is not a roadblock but rather an opportunity for improvement and growth.”

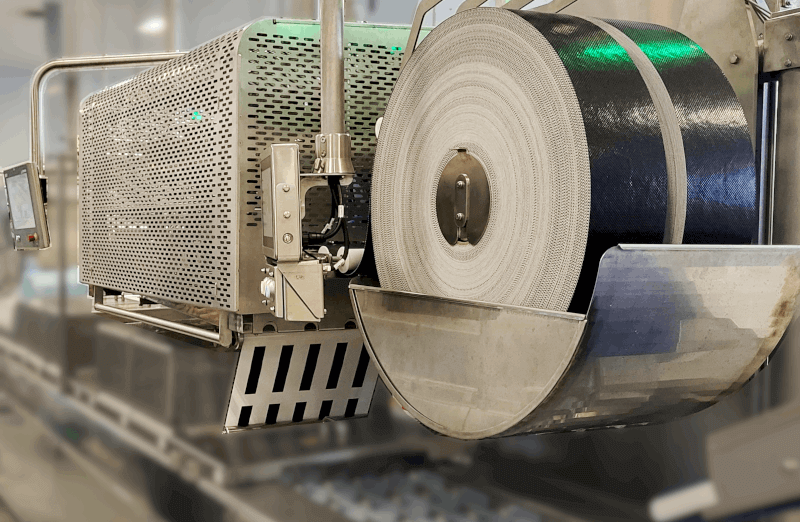

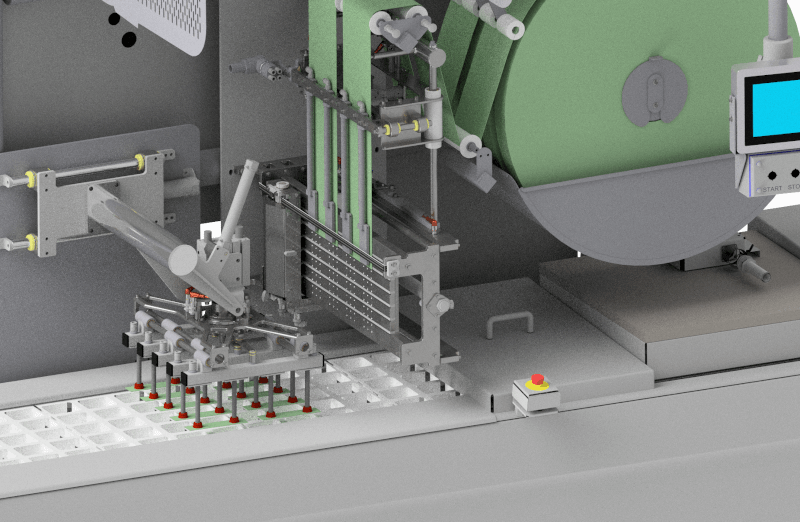

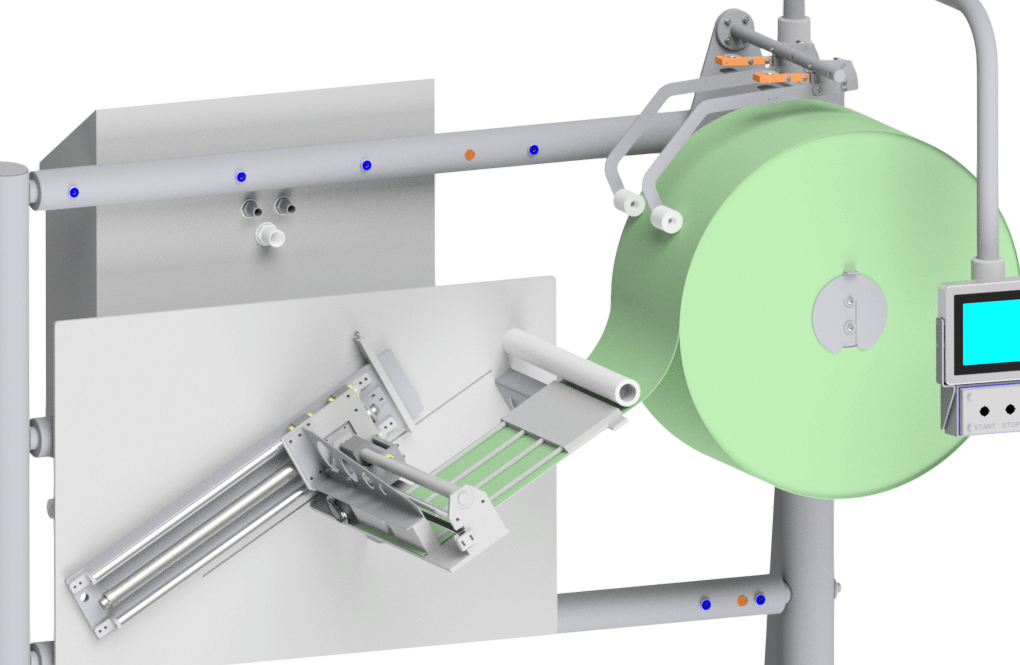

Inline absorbent pad applicator

for the food industry

A few years back a customer asked us to develop an inline applicator to weld absorbent pads onto the top film and install it on their existing thermoforming packaging line.

It was early decided to cut the pads from roll material for easy material handling. The result was cheaper pads due to lower material cost and fewer parts to handle and it freed up two operators on the production line. But best of all it improved the positioning precision of the pads and eliminated rejected packages due to misplaced pads ending up in the seal.

- The Cut, Place and Weld Applicator (CPW) – proved to be a real success

With this in mind we have developed additional two pad applicators for the more common thermoforming packaging lines:

- the Pad in Tray Applicator (PT) – for placing pads into trays

- the Cut and Place applicator (CP) – for larger tray sizes

Push & Dose

Experience unparalleled precision and elevate your sprinkling routine with Push & Dose, the world’s first sprinkling feature developed for flexible pouches.

Invented and patented by Fimtech. Commercialized in close cooperation with leading pouch machine manufacturers.

Find out more on PUSHDOSE.COM!