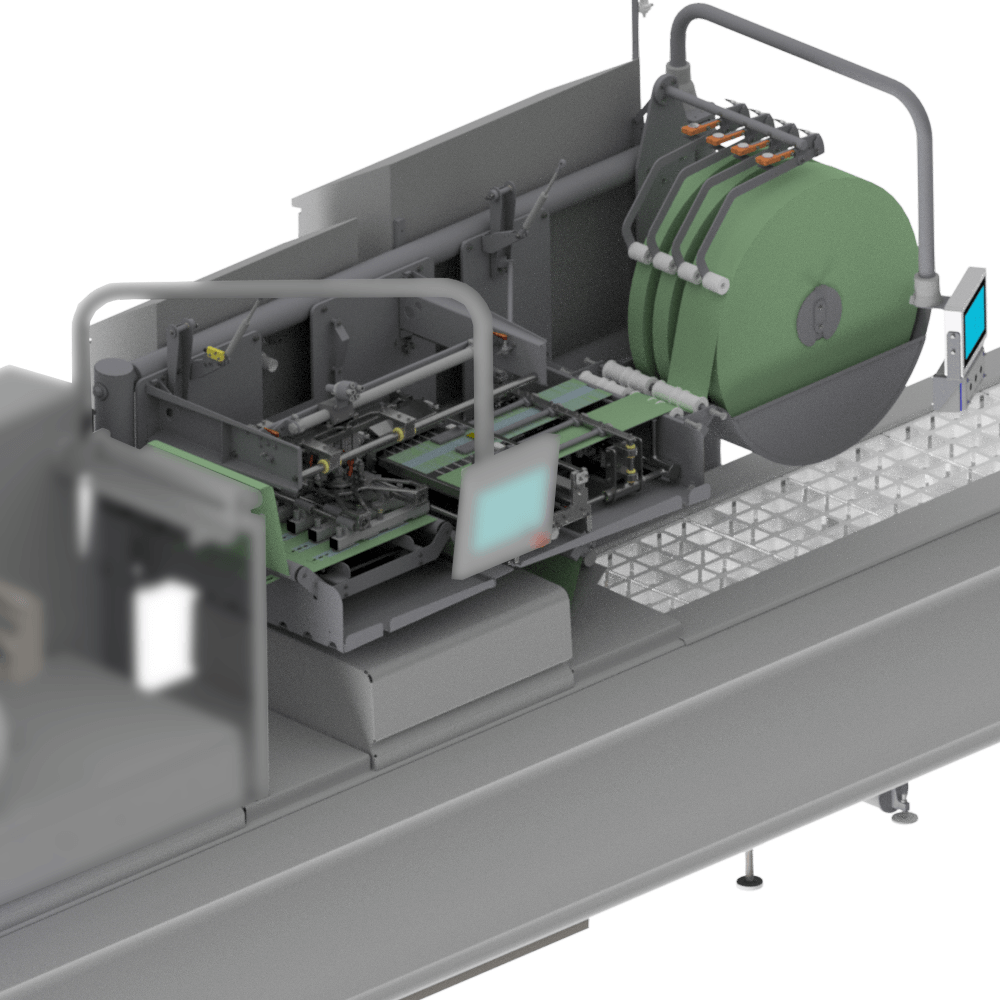

Absorbent pad applicator for topfilm

Cut, Place & Weld pad applicator

Our versatile Cut, Place & Weld module designed for seamless integration with your thermoforming packaging

machines.

The pads are precision-cut from a rolls and automatically sealed onto the top film, requiring only a minimal working surface. The module is easy to clean, have low maintenance and provides a reliable solution that optimizes human resources and increases product quality and production yield.

Download the sales prospect here!

Main features

- Places up to 160 pads per minute

- High speed, fully automated machinery

- Supports multiple pad configurations

- Utilizes roll-fed material

- Easy maintenance

- Supports food grade cleaning

Flexible & Modular

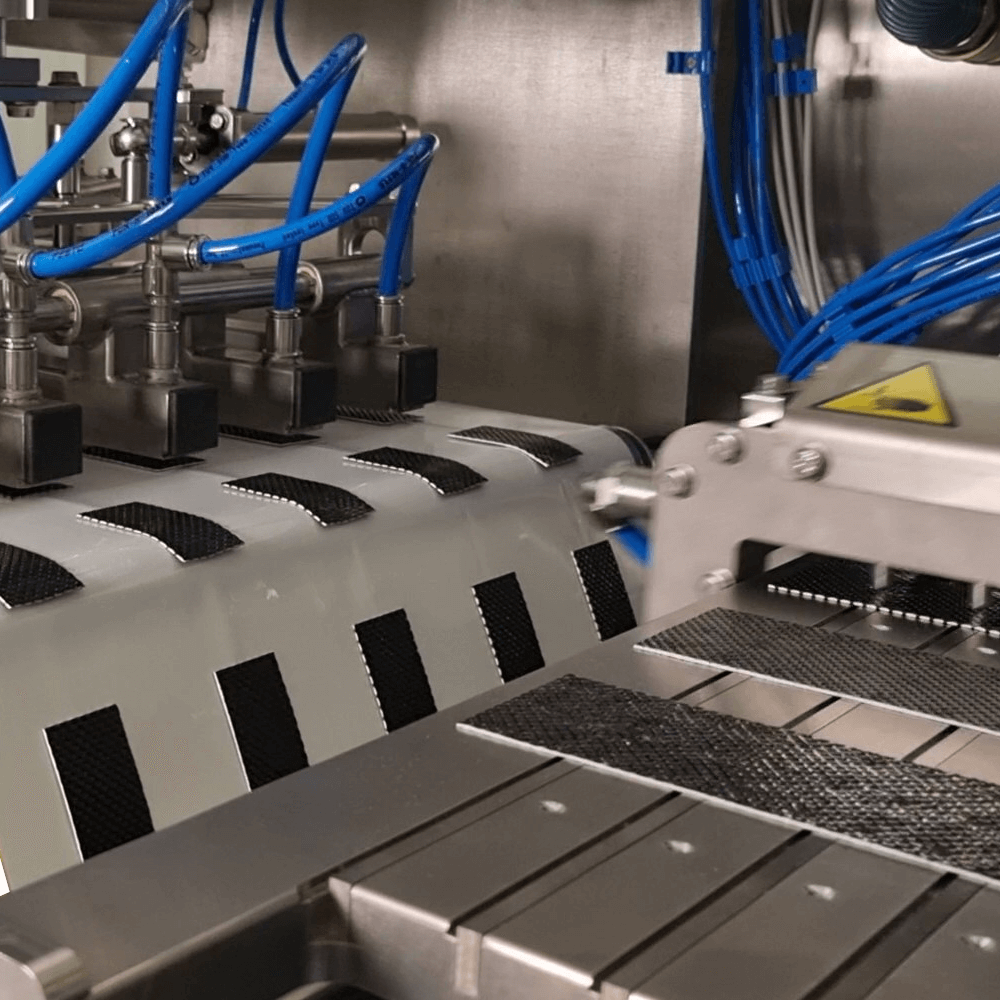

Multiple pads are cut from a roll and smoothly transfered to the welding station where the pads are welded on to the top-film. By changing a few size parts to make pads of a different length, enables to pack various products on the same production line.

The compact design ensures an easy integration into any existing thermoforming packaging machine line. All movements solely by pneumatics and constructed from durable stainless steel, it is a dependable, low-maintenance unit suitable for food-safe environments.

Main benefits

- Cost savings by replacing manual operations

- Cost savings with no need for pre-cut absorbent pads

- Cost saving as yield improves (exact placement of pads)

- Cost savings with easier stock (same roll for different sizes)

- Easy integration into existing production lines

- Improved food safety by limiting manual handling of pads