“Kick start” of a production line

It was during a few intensive months at the end of 2020 that Sfactor installed a completely new production line for certified respiratory face masks in their premises. When the machine arrived from Asia, it was evident that the transportation had resulted in a few damages to some modules. In addition to this, the supplier was not able to perform the ordinary on-site commissioning, due to COVID-19 travel restrictions. It became very clear for Sfactor that they needed expert help from Fimtech. Being neighbor companies in Tønsberg, made it even more convenient with respect to get speed into the process.

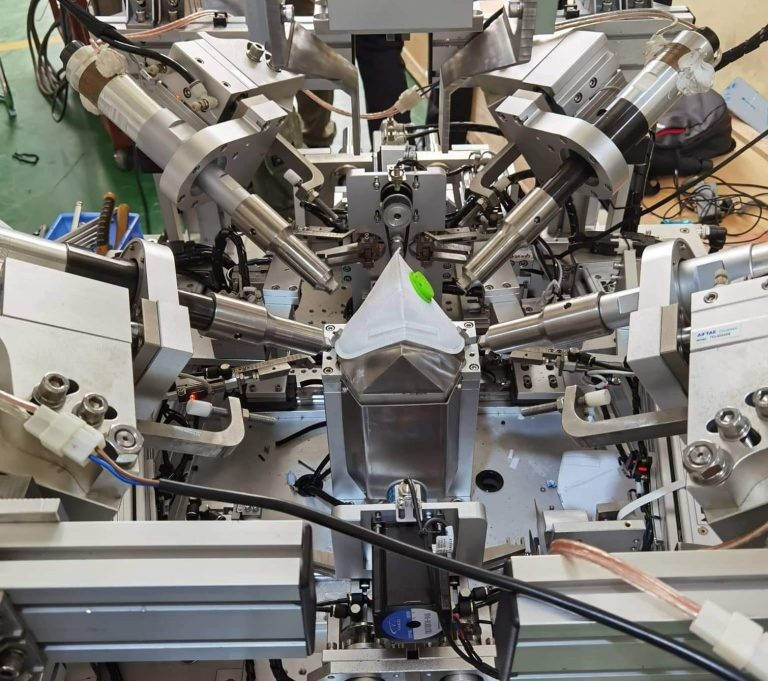

“On this job we were able to use many aspects of our core knowhow. We helped Sfactor from the very start; with installation, where placing and levelling of the machine is essential. We designed and delivered new mechanical parts to replace damaged ones. We even made a few new items to improve some functions and components, where we found the original design to not be optimal.” Says Arild, lead mechanical engineer at Fimtech.

Our electrical technician helped out with the electrical installation and debugging. We discovered a few of the many sensors that had been wrongly wired from the supplier. We assisted with an automation engineer who helped the customer to understand the automation logic.

When each function on the production line had been installed and debugged, Fimtech together with the Sfactors own process engineers managed to fine-tune the production flow, achieving great improvements in productivity maintaining the required high quality on our products.

We had never been able to start production so quickly without the much valuable support of Fimtech. And we really appreciate how they share their knowledge and makes us become better at what we do!