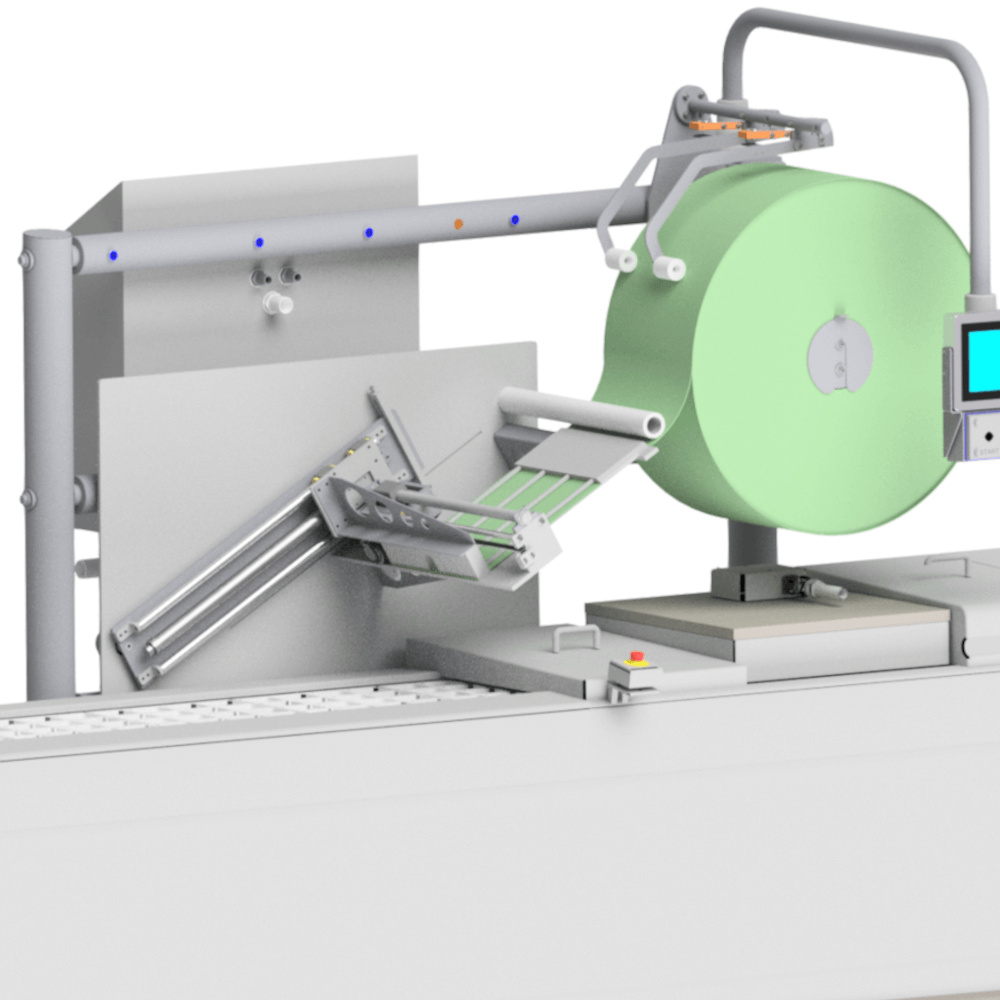

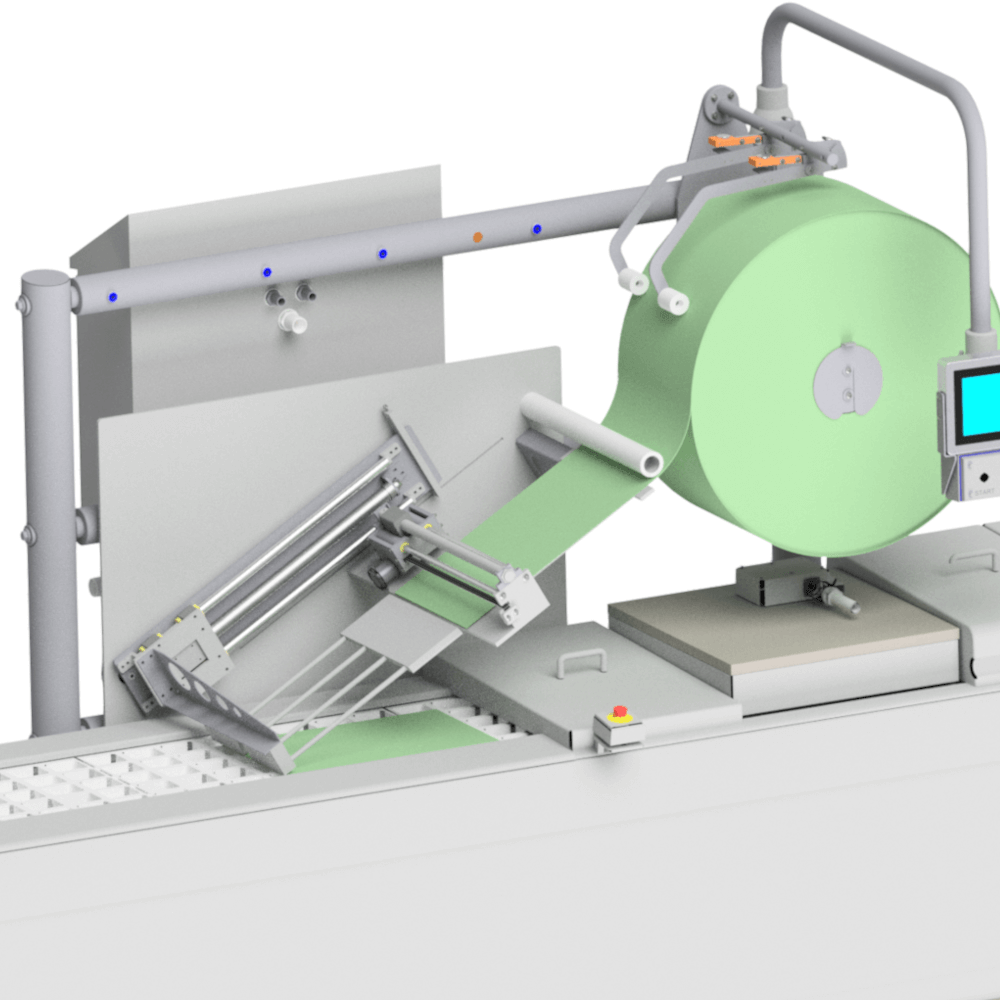

Absorbent pad applicator Cut & Place

Cut & Place pad applicator

Our versatile Cut & Place module designed for seamless integration with your thermoforming packaging

machines.

The pads are precision-cut from rolls and automatically placed in trays. Just a small working surface is required. Our module is easy to clean, have low maintenance and provides a reliable solution that optimizes human resources and increases product quality and production yield.

Main features

- Up to 12 strokes per minute (pad lengths up to 500mm)

- High speed, fully automated machinery

- Supports multiple tray & pad configurations

- Utilizes roll fed material

- Easy maintenance

- Supports food grade cleaning

Download the sales prospect here!

Flexible & Modular

The applicator cuts efficiently one or more pads and seamlessly transfers them to the tray in a continuous motion. This process is facilitated by smoothly moving the pads from the cutting station into the tray. By changing the pad roll width and define a new length in the operators panel, the applicator accommodates the production of various tray sizes on the same production line.

The compact design of the Cut & Place applicator allows for easy integration into any existing thermoforming packaging machine. All movements solely by pneumatics and constructed from durable stainless steel, it is a dependable, low-maintenance unit suitable for food-safe environments.

Main benefits

- Cost savings by replacing manual operations

- Cost savings with no need for pre-cut absorbent pads

- Cost saving as yield improves due to an exact placement of each pad

- Cost savings due to less bespoke pre-cut pads to manage/stock

- Easy integrationinto existing production lines

- Improved food safety by limiting manual handling of pads